Is Your Chemical Company Experiencing Labor Pains?

They tell you to breathe through each wave of pain. They say they don’t know how long each phase will last, “but you’ll get through it!,” they shout through forced smiles. But the pain is so excruciating, you have to wonder, will we make it?

Hiring in the manufacturing realm in 2021 is difficult.

Oh, you thought we were talking about another kind of labor pains?

We don’t want to make light of things – in both cases, there can be some serious issues – but there’s also a pretty dramatic difference between these labor pains and the ones you may be experiencing in the current industry landscape.

Generally speaking, the labor pains associated with childbirth have a happy ending, and the pains go away shortly after the baby takes its first breaths.

We’re still not sure about that happy ending in the manufacturing sector.

Returning to Post-Pandemic Production

You’ve probably seen the question on the employer job listing forms: Can this job be done from home? In countless industries, businesses have adapted to allow employees to work remotely.

Unfortunately, chemical manufacturing employers don’t have the option of saying yes to that question.

With the uncertainty of rebuilding a labor force in a post-Covid world, manufacturing plants continue to wrestle with questions related to costs and other practical maintenance concerns associated with starting and stopping production lines. Add in the stress that comes with a sometimes-still-unreliable supply chain and industry professionals may be asking questions like:

Many plants are struggling to reopen at sufficient capacity to support customers, let alone profits.

While the humanitarian questions are important, so are the business issues. It’s easy to understand why parents choose to stay home to help manage their children’s on-again, off-again school schedules, or why a child who’s grown up may want to be home with an aging parent. But it’s also clear that production jobs demand steady workers. On-again, off-again manufacturing doesn’t keep plants open.

What’s a chemical manufacturing operation to do?

Baby, We Got This

Much like with parenting, a helpful way to handle labor pains is to have a reliable partner. In fact, that’s true for the initial recovery period and for the long haul, as well.

Like new parents, manufacturing plants couldn’t be fully prepared for the ups and downs of the pandemic and the changes it would bring to our everyday lives. It’s still hard to predict what the future holds. But experience, resources and determination allow us to meet every new challenge.

It’s been said that the pandemic forced several decades of change in the workforce to happen in just about a year. Ouch! That kind of change is mighty uncomfortable. But we like to think there’s a bright side and that some of these “labor pains” are actually growing pains.

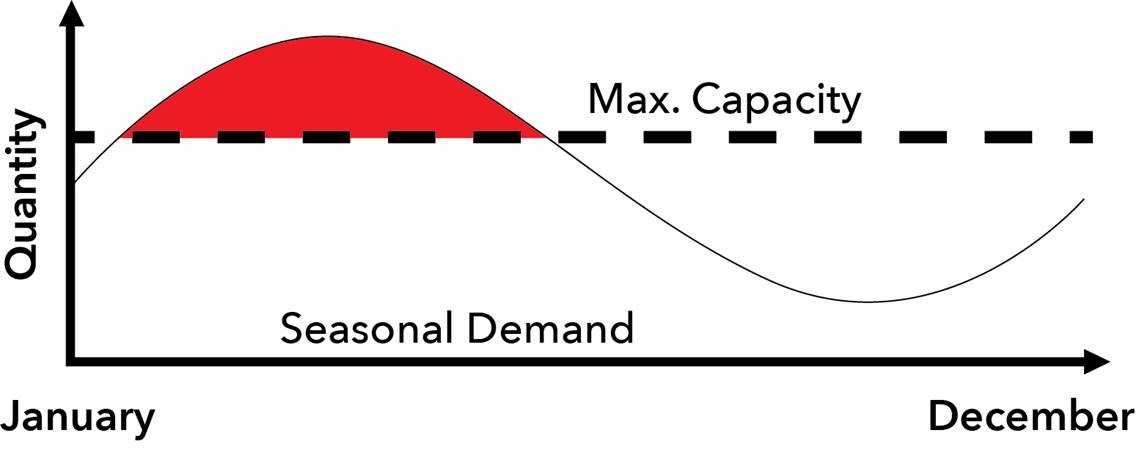

Many chemical companies find partnering with a toll blender is a great way to offer new products. A contract manufacturer like Royal, with an experienced staff and the expertise to handle small or seasonal runs, custom blends for special customers or other low-volume, high-margin variations of a regular product line can provide your company with new or additional revenue streams.

What’s it like to have a chemical manufacturing partner? Royal Chemical clients focus on managing their business – their baby, if you will – while our five locations and experienced staff handle the production, logistics and distribution.

- Full Logistics Support – This includes procurement and valuable warehousing and inventory management services for bulk ingredients as well as finished products.

- Nationwide Delivery (and Freeze Protection) – With five strategically located facilities, Royal can ship to 80% of the country within a day and help insulate your business from regional outages due to catastrophic weather events.

- Operational Responsibility – Royal is responsible for the workforce, from hiring and training to protection and liability (including the important acronyms we don’t need to spell out, like OSHA, EEOC, DOL and EPA). Equipment and technology upgrades are also solely our concern, not yours.

- Cash Flow Management – We’re not in the credit business, but most of our clients realize improved liquidity when they can better forecast freight and delivery charges. It’s also a relief to know your payment isn’t due to us until your product is on its way to your customers!

Let Us Help You Take Care of Your Baby!

Like a good parenting partner, Royal is protective of your “baby.” While the quality and consistency of your product is ensured, we guard your formulas and will never compete with our customers by producing our own private labels.

In other words, your baby is our primary concern.

We love our analogies, but we do not take partnerships lightly. When you’re ready to discuss how we can work together to consistently deliver product to your customers and help your business grow, let’s talk.

And hey, maybe the pandemic didn’t sideline your production – it just interfered with your growth plans or derailed a planned product expansion. In that case, we can still help you get back on track.

Talk to a team of experts with 80+ years of experience in the chemical manufacturing and toll blending industry. Schedule your free, no-obligation consultation with Royal Chemical here.

Talk to an Expert

Streamline Your Chemical Manufacturing Process

Royal Chemical’s expertise in blending, packaging and shipping can save you time, reduce costs and deliver consistent results.