Managing Surges in Chemical Product Demand (Minus the Stress)

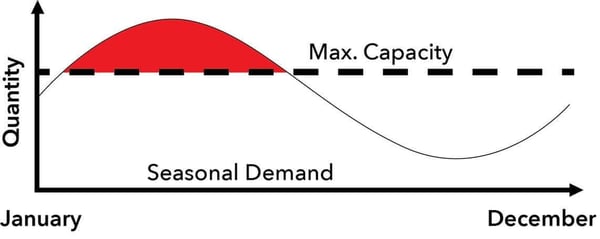

Everybody gets excited when sales orders come flowing in. But when strong orders turn into a flood, the excitement can turn to panic as you try to figure out how to keep pace and maintain commitments. This pattern can happen with any product line, but is especially common in seasonal industries. The stress of trying to keep pace with demand is a lot better than the stress associated with too little demand. But it’s stress, nonetheless. You’ve worked hard to develop customers and don’t want to lose them when they need you most.

The common responses are predictable and fraught with challenge:

- Delay delivery dates – At best this results in disappointed customers, at worst it causes them to completely miss an opportunity such as a growing or de-icing season.

- Force the manufacturing staff to maximum overtime – This may be appreciated when Christmas bills are due, but over an extended time leads to worker burnout and inefficiencies, quality and safety problems, and eventually to turnover.

- Hire additional staff – Easier said than done in this day of ultra-low unemployment. Plus, this takes time and taxes your HR and training staffs. Then what do you do if the order surge subsides?

- Hire temporary workers – Sometimes this is an effective solution, but temps are frequently unreliable and will certainly require training and extra supervision. Any shortfall in these efforts can result in quality problems or safety risks.

Okay, but what else can be done? Turning to a reliable contract manufacturer is often the preferable solution.

Contract manufacturers specialize in the manufacturing process and do not face all of the organizational burdens associated with developing and marketing proprietary product lines. These experts serve broad customer bases, which helps to level out demand—when one industry is up, another will be down. This makes it easier to manage capacity, and also offers the additional benefit of purely variable cost. Turn on production when you need it, and off when you don’t.

When selecting a contract manufacturer, look for a company with:

- A long track record of delivering on commitments

- Highly professional staff and strong Quality and EHS programs

- Ample capacity and storage facilities

- Strong raw material supply relationships

- Full range of services including freight arrangements, warehousing, order fulfillment and inventory management

The more advanced planning the better, as it will certainly take two weeks and commonly four weeks to get production rolling. Supplying a detailed list of approved materials, manufacturing instructions and QC specs in advance will prepare the contract manufacturer to respond quickly when needed. This may seem like extra work, but preparing an alternative source of product production is a sound part of a disaster planning program. You might even save money on your business interruption insurance.

If your stress level rises with greater demand for your product, contact Royal Chemical to share your unique requirements and questions. You may discover that stress relief is closer than you thought.

Talk to an Expert

Streamline Your Chemical Manufacturing Process

Royal Chemical’s expertise in blending, packaging and shipping can save you time, reduce costs and deliver consistent results.