Bulk vs. Non-Bulk Packaging: What All Chemical Manufacturers Should Know

In today’s global market, many companies are shipping large quantities of chemicals at one time, or in bulk, rather than paying high per unit costs to ship small amounts of product. When shipping bulk vs non-bulk packaging, companies must comply with certain regulations and requirements. While a small pallet of hazardous materials leaking still poses a threat, it’s considerably less of an issue than a full tanker truck overturning and spilling on the highway.

If your business is expanding into shipping bulk quantities of your product, you must take care and develop safety protocols in line with bulk packaging requirements. This article provides an overview of bulk packaging must-knows as well as requirements for chemical packaging, shipping, labeling and handling in large quantities.

What is bulk packaging?

As a standard definition, “bulk” is considered to be over 119 gallons, or 450 liters, of liquid. Solids are measured differently. “Bulk” is legally defined as being over 882 pounds (400 kg) or having a volume of over 119 gallons. Gasses are further defined as “bulk” when their volume exceeds 1,000 pounds, which is again 119 gallons described as a measurement of volume.

To put the “119 gallons” into perspective, two 55-gallon drums are 110 gallons. The 55-gallon description is nominal rather than an exact precise measurement of how much material might literally be stored in the drum, so it gives nine gallons of leeway toward how much liquid is really contained. This is a practical aspect of how an inspector can do their job by assuming the two drums are carrying less than the legal threshold.

When bulk packaging contains hazardous or non-hazardous materials, common sense dictates employees follow basic safety regulations when handling, at the very minimum, those recommended by OSHA. Such regulations include how the chemicals are stored and what types of safety gear is required when handling the container or when using the actual material outside of storage.

Further, there are environmental laws which typically tell us how to dispose of potentially dangerous materials. Regulations spell out how to preemptively handle materials to avoid a spill and how to maintain measures to mitigate the results if a spill actually occurs. To avoid fines and keep employees safe, regulatory compliance must be made a priority from production and to final delivery.

Transporting hazardous materials in bulk

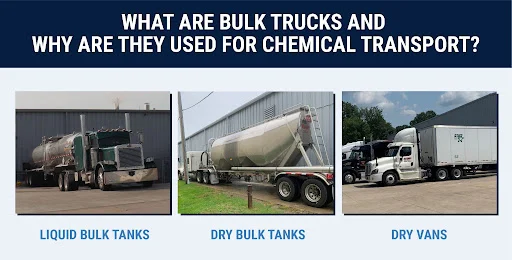

Tankers, whether as a single vehicle or rail cars, are designed to haul far much more than the standard 119 gallons, which constitutes the minimum for bulk packaging. For example, the tanker which is towed by a tractor trailer to deliver gasoline or diesel fuel to individual gas stations has been seen by anyone who has driven on highways or surface roads.

Another common example of the self-enclosed vehicle unit which most people are familiar with would be the truck which delivers heating oil to individual residences, or perhaps propane to businesses and homes which use their own tanks instead of public gas lines. Rail cars are perhaps less well recognized, but many of them can be linked together on a short or long distance train delivering oil, fuel and numerous petrochemicals.

Labeling requirements for bulk hazardous materials

Registration and labeling of hazardous and non-hazardous materials are a matter of federal and local law, influenced by international standards. Bulk material is always going to require some form of placard to identify what is in the container. This is so in case of an emergency, first responders know what is in the container and how to treat it. In the worst case scenario of an accidental spill, the label allows responders to immediately know what safety equipment they need and how to approach the clean-up process.

Best packaging materials for transporting bulk hazardous materials

It isn't so obvious whether steel tankers are lined as it is easy to recognize the exterior material of a fifty-five gallon drum, but the most basic materials of construction involved with various types of steel, with and without linings, transport and storage of hazardous and non-hazardous are metal or plastic drums.

Metals Drums

There are different types of steel which work better for specific purposes. Sheet steel may work best for drums and tanks, but even that can be either stainless or carbon steel. Each of these have various grades of hardness and properties which may be better suited for different types of chemicals.

Plastics Drums

Differing styles of plastics and the relatively inexpensive cost of plastics each has its own properties and tend to be the most common form of storage for hazardous materials for less than bulk.

A number of other plastics can serve more specific purposes. In some cases, a plastic was designed and developed only for the transport of a single material without the versatility of serving other functions. Such determinations usually require an in-house engineer or outside consultant to determine what will work best and what is required by regulations and laws.

Bulk vs. non-bulk packaging: The bottom line

The difference between bulk and non-bulk packaging comes down to environmental health and safety. Bulk packaging is an absolute requirement in a post-industrial era where companies must ship large quantities of chemicals to compete, yet inherently creates multiple risks.

Non-bulk packaging can also cause damage to health and safety, but doesn't do so at the same level as a train load of hazardous material. If your business depends on shipping hazardous materials in bulk, always put safety and compliance with regulations at the top of your priority list.

Looking for the best bulk packaging materials for your product? Interested in auditing your safety regulations? Royal Chemical has over 80 years of experience in handling and shipping bulk hazardous materials. Our team of experts are more than happy to provide a free consultation to answer your questions. Get in touch with the Royal Chemical team here.

Talk to an Expert

Streamline Your Chemical Manufacturing Process

Royal Chemical’s expertise in blending, packaging and shipping can save you time, reduce costs and deliver consistent results.