The Crucial Role of Labels in Chemical Manufacturing

“Safety first” is not just a talking point at Royal Chemical. We know that safety, including stakeholder protection and regulatory compliance, is priority one for our customers. Accurate chemical labeling plays a vital role in any safe, effective chemical manufacturing process.

Why is chemical labeling so important? From cradle to grave, proper labeling allows for tracking and traceability for safety and compliance purposes, assists in quality control, boosts brand identity and supports effective communication.

When it comes to labels in chemical manufacturing, whether you’re in the business of industrial & institutional cleaning, car care, chemical distribution, food processing, plant cleaning, janitorial and household cleaning, laundry chemicals, sanitizers and disinfectants or metal cleaning, you can trust Royal Chemical’s experience and expertise to ensure your materials are labeled for the best outcome.

Safety: Accuracy Is Everything

At Royal Chemical, labels are a manufacturing requirement to help ensure safety and compliance. Labels communicate essential information about the materials, including chemical composition, hazard warnings, handling instructions and disposal methods.

A proper label on every container – whether it contains raw materials, intermediates or finished products – helps mitigate the risk of mix-ups, mistakes or safety hazards. For example, if you work with hazardous ingredients like oxidizers or corrosives, you must have proper hazard labels to indicate storage and shipment requirements and compatibilities.

Accurate, legible chemical labels are also essential when it comes to properly handling and mixing materials. Risks are reduced, employees are kept safe and consumers are protected when labeling standards required by federal regulatory agencies like the Environmental Protection Agency and the Occupational Safety and Health Administration (OSHA) are met.

As of 2015, OSHA adopted the Globally Harmonized System (GHS) guidelines. The GHS is a set of international labeling and classification standards. The GHS:

- Specifies criteria for classifying hazardous materials

- Specifies information needed on safety data sheets

- Ensures the safe use, transport and disposal of hazardous chemicals

- Creates a unified approach to labeling hazardous materials

All products produced at Royal Chemical comply with these guidelines.

Maintaining Quality

Like safety, quality control and assurance are critical to contract chemical manufacturing. Labeling directly supports quality efforts. For instance, lot numbering provides identification and traceability in case there is a need to locate a specific batch for quality assurance.

As mentioned above, chemical labels provide critical details like batch numbers and they also inform expiration dates, which may drive operational processes like inventory management.

Royal Chemical has an extensive review process for all customer labels and Safety Data Sheets (SDSs) for compliance and consistency. Our review process is a legal precedent that we take extremely seriously. We will not begin manufacturing unless the finished good label meets the requirements, and we will not release products for storage and shipment until their labels are inspected for accuracy.

We also offer resources and guidance to help clients ensure their SDSs match their labels.

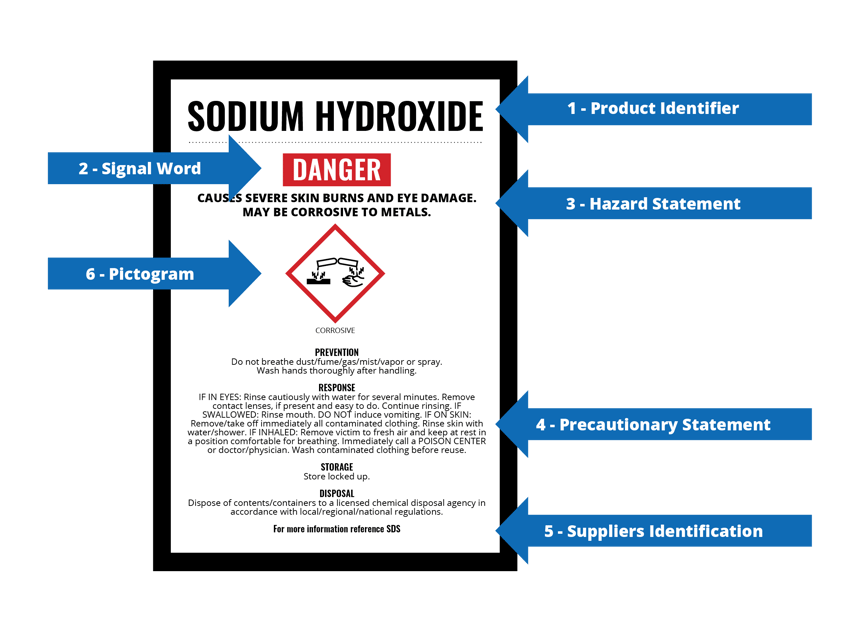

For instance, to comply with GHS, every label must include the following six elements:

- Product identifier – How the chemical is identified — for example, all warnings, indicators and DOT information. It must identically match what is listed on the SDS.

- Signal word – A single word, such as “danger,” used to indicate the severity of the chemical’s potential hazard

- Hazard statements – A phrase that describes the nature of the product’s specific hazard.

- Precautionary statements – A phrase describing actions to take to prevent adverse effects from exposure to or improper handling of the chemical.

- Supplier identification – Name, address and phone number of the chemical’s manufacturer or supplier.

- Pictograms – OSHA-designated images that are used to communicate the chemical’s effects.

At Royal Chemical, we utilize a Technology Transfer Package (TTP) to ensure an efficient onboarding process with our contract chemical manufacturing customers.

The TTP communicates key details, including:

- Safety data sheets

- Packaging and labeling instructions

- Quality control requirements

- Certification requirements

- Formulation details

- And more

Clear Communication & Branding

Proper labels are a clear, concise communication method that allows for accountability between all parties in the manufacturing process – from the manufacturer to the regulator, to the distributor and, ultimately, to the end user.

The goal of chemical labels is to ensure smooth operations and to build trust among all stakeholders. That’s why labels are an important part of your product’s branding and marketing efforts.

Important also is your company’s logo and associated branding details like fonts and colors. Also, remember size matters. Match the information and size to fit the product’s packaging for an effective design. You want your target consumers to recognize your brand and product quickly so they become repeat customers.

For a good consumer experience, it’s essential to include material usage instructions. Remember to provide these details on your label so end users employ your products correctly. Building trust and creating a distinctive brand starts with your label.

The importance of labels in chemical manufacturing cannot be overstated. Labels ensure safety and compliance, help you maintain quality control and enhance your brand. At Royal Chemical, we’re here to assist you in all aspects of contract manufacturing – including proper, effective labeling.

Contact us today to discover how we can help you achieve your goals with liquid blending, powder blending, packaging and other chemical contract manufacturing solutions.

Talk to an Expert

Streamline Your Chemical Manufacturing Process

Royal Chemical’s expertise in blending, packaging and shipping can save you time, reduce costs and deliver consistent results.