An Introduction to Physical Hazardous Material Classes and Categories

As a chemical manufacturer, importer or distributor, you need to have the foundational knowledge of hazardous material classes and categories. Regulations require hazardous materials to be properly labeled to inform all personnel along the supply chain of any risks or dangers the material inside can pose.

If an accident occurs and the chemical leaks onto the road or comes in contact with humans, first responders can use the identifiers on hazardous chemical packaging to assess the situation and determine a plan of action. Failure to place hazard identifiers on packaging or safety data sheets can result in fines, shipping delays, withdrawal of shipping privileges and even jail time.

If you’re just dipping your toes into the world of hazardous materials classes and categories, you may find yourself confused by a lot of seemingly contrasting information. This system is technical and can be difficult to understand, but to help, we’re breaking down the fundamentals of hazardous material classes and categories as they apply to the physical hazards of chemicals.

What Is the GHS?

As the world evolves and globalization becomes the norm, the global trade of chemicals has ramped up. To combat the risks of chemical transport and create a comprehensive system for shipping and receiving hazardous products, the United Nations adopted the Globally Harmonized System (GHS) in 2003. The GHS:

- Specifies criteria for classifying hazardous materials.

- Specifies information needed on safety data sheets.

- Ensures the safe use, transport and disposal of hazardous chemicals.

- Creates a unified approach to labeling hazardous materials.

Has the U.S. Adopted the GHS?

In the years that followed, every country adopted the GHS standards in some form. However, that doesn’t mean every country follows the exact same, consistent system. The reason GHS standards are so complicated is twofold: One, the standards themselves are often up for interpretation. And, two, many countries have made slight tweaks to the system to make it work for them.

The U.S. played a huge role in creating and instating the GHS. The American Occupational Safety and Health Administration (OSHA) regulators committed to adopting its guidelines on a timeline that concluded in 2015. However, while the U.S. was adopting guidelines under OSHA, Canada was creating the Workplace Hazardous Materials Information System, or WHMIS, their own hazard communication system. And across the pond, Europe was working on the CLP Regulation, their own interpretation and adoption of GHS standards.

As you can see, the GHS was already a fairly technical system, and its adoption by different countries and cultures around the world has led to an overload of confusing information online that may only apply to one specific country. Even now, regulatory bodies and chemical businesses have created their own interpretations of their country's standards, which were derived from GHS physical hazard standards.

For the purposes of this article, we’ll be focusing mainly on the U.S. and OSHA’s definitions of physical hazardous classes. But we do encourage you to look into some of the fascinating differences in each country’s interpretation of the same standards.

Hazardous material groups

The GHS defines three main hazard groups, the first step to breaking down the full spectrum of hazards.

- Physical hazards group: The criteria for these hazards is based on their physical or chemical properties. These hazards can cause physical harm to anyone using them. Examples include flammables, self-reactive substances and corrosives.

- Health hazards group: These hazards can cause adverse health effects in users through exposure. Examples include acute toxicity, carcinogenicity and respiratory sensitization.

- Environmental hazards group: This is the hazard group most often forgotten as it is not recognized or enforced as a hazard in the U.S. and Canada. This group of hazards can have a negative impact when released into the air, water or land. Examples include acute aquatic toxicity and rapid bioaccumulation potential.

Physical hazards is the largest of the three groups, with nine potential classes (or 16 potential classes in Canada). Next, we’ll take a closer look at each type of physical hazardous product class.

Physical Hazardous Material Classification Chart

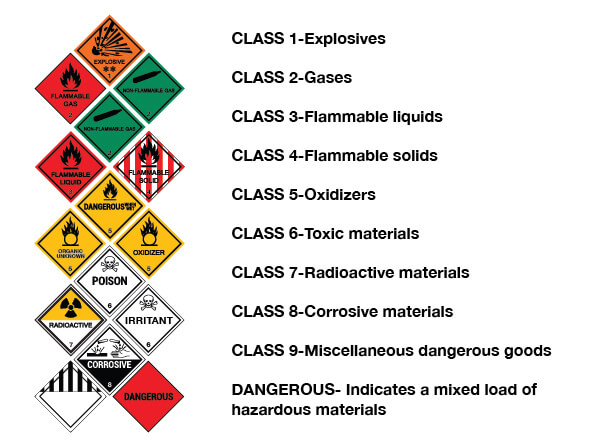

A hazard class describes the nature and danger of a chemical hazard by putting it into a group with materials that have similar properties. How many different hazard classes are there? The GHS identified 16 classes of physical hazards. OSHA sometimes recognizes 16 separate classes and sometimes combines them together for a total of nine classes. The U.S. Code of Federal Regulation specifically identifies nine classes instead of 16. The nine are as follows:

Class 1: Explosives

Explosives are materials with molecules that can rapidly deteriorate from their solid state into very hot gas, creating a sudden, violent effect. Because of their volatile nature, these items aren't usually shipped by air. Examples include fireworks, mercury fulminate and gunpowder.

Class 2: Gasses

Gasses are substances that are completely gaseous at standard atomic pressure. They are usually shipped under pressure to reduce their volume and save space on carriers. This category covers both flammable and nonflammable gases. Examples include fire extinguishers, helium and aerosols.

Class 3: Flammable Liquids

Flammable liquids are liquids with flashpoints of 60 to 65 degrees Celsius or lower that give off flammable vapors at specific temperatures. Any liquids that pose a threat of fire fall into this category, which encompasses liquids, liquids containing solids in solutions and mixtures of liquids. Examples include gasoline, kerosene, paints and alcohol.

Class 4: Flammable Solids

Flammable solids are solid materials that pose a fire threat through self-reaction or reaction with another element like water or fire. This class encompasses a wide variety of solid materials, including those that burn easily, like paper, and those that are only liable to react if exposed to specific shocks or temperature changes. Some burn explosively, some burn slowly and others produce toxic gasses if they catch fire. Examples include matches, activated carbon and oily fabrics.

Class 5: Oxidizing Substances

Oxidizing substances readily give off oxygen that can contribute to or cause combustion in other materials. They can react with other substances barring any other changes in the environment simply because of the amount of oxygen they produce. Examples include bromine, hydrogen peroxide and ammonium nitrate fertilizers.

Class 6: Toxic Substances and Infectious Substances

Toxic substances can cause a physical reaction in humans if they're ingested or come into contact with skin. These chemicals can cause serious injury, harm or death, damaging the human body in whole or in part. Examples include cyanide, vaccines and arsenic. Infectious substances are those known to contain pathogens harmful to humans. Examples include viruses, bacteria and fungi. The human body should not come in contact with, inhale or ingest any of these substances.

Class 7: Radioactive Materials

Radioactive materials have radionuclides, or unstable atoms, that decay over time and emit radiation above safe levels. As the atoms change, they emit invisible radiation waves that can alter the human body’s chemistry or biology. The severity of the alteration depends on the type of radiation and duration of exposure. Radiation in any dose is extremely dangerous to human health and must be handled with caution. Examples include uranium, radon and medical isotopes.

Class 8: Corrosives

Corrosives are highly reactive substances that produce a chemical effect when in contact with certain other materials. They can damage and disintegrate inorganic materials and can cause damage to organic tissue. If corrosives leak in transit, they can even damage the vehicle on which they travel. This class encompasses all corrosives, whether they're in a solid, liquid or gas state. Examples include battery acids, mercury and dyes.

Class 9: Miscellaneous Hazardous Materials

This is a catch-all class for hazardous materials that don't easily fit into the first eight classes. The thing these items have in common is that they're dangerous and can pose a threat during transport. Examples include, but aren't limited to, dry ice, first-aid kids, asbestos, flares, life rafts, vehicles, chainsaws and even fabric repair kits that may contain a flammable adhesive. Again, these products don't fit neatly into another category or have more than one clear hazard crossing into two or more other classes.

Hazard Category Numbers

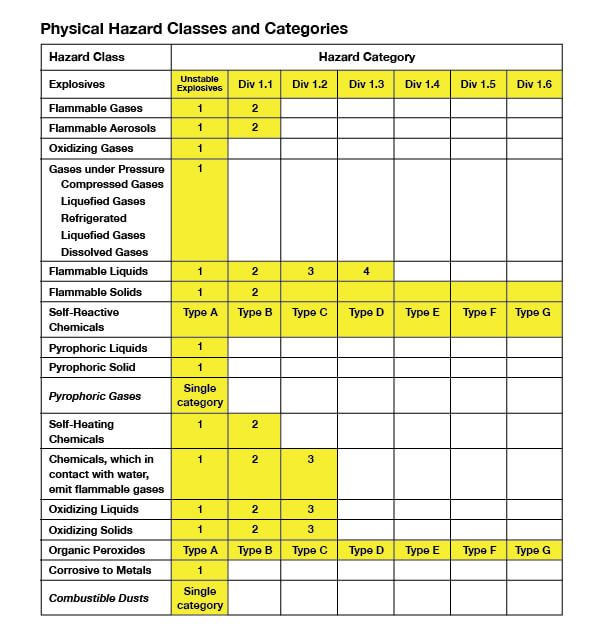

Now that we’ve broken the spectrum of hazardous materials down into a group (physical hazards) and discussed all nine classes, we can move further down the GHS and OSHA classification into hazardous materials categories. Each class contains a specific number of categories that describe the nature and, sometimes, the degree of danger posed by the hazard.

Categories are tricky. A chemical can fall into only one class but can fall under multiple categories within that class. The category usually consists of a number (one through four), a letter (A, B, C, etc.) or even a word. Most often, you'll see a hazard category indicated by one number, but on occasion, a product falls into subcategories, indicated by the category and a letter, e.g., Category 1A or Category 2B. The beginning of the scale always indicates a greater degree of hazard, so 1 and A have more risk than 2 and B, and subcategory 1A has a greater risk than 2B.

To further complicate things, not all classes have the same number of categories. Some have only one category, some have two, some have three and others have four, etc. The explosives class actually has six categories called “divisions,” and the self-reactive chemicals class has six categories called “types.” The system is complicated and requires study and memorization on the part of chemical professionals.

This chart can be used as a cheat sheet to help you remember which classes have which categories or divisions. Keep in mind this chart references the 16 physical hazardous classes set forth by the GHS rather than the nine classes mentioned above that are recognized by the U.S. Code of Regulations.

Process for Classifying a Hazard

If you're a manufacturer of hazardous materials, physical or otherwise, you must determine your hazard class and category. If you're a downstream user of the chemicals, you don't need to determine classification. This responsibility lies only with the original creator.

There are five general steps to identifying your hazard. Remember, throughout this process, only the intrinsic properties of the chemical should be considered.

- Identify relevant data regarding the material’s hazards. Collect all the data you have available and silo it in one space.

- Review the data to determine if the chemical is hazardous and, if so, what group those hazards fall into (physical, health or environmental).

- Test your chemical to determine potential hazard classes or check scientific data and aggregate your findings.

- Identify all hazard classes that apply to the chemical.

- Identify the hazard category within each applicable class to determine the severity and risk the chemical poses.

It sounds simple when you break it down, but the process of classifying hazards takes knowledge and practice. The best way to tackle the process is by having as much raw data about your chemical as you can and then cross-referencing that data with existing data on hazardous materials. For the same time and accuracy, it’s suggested you consult and cross-reference from the same three to five reliable sources each time you repeat the classification process.

Communicating Hazardous Material Classification

As we mentioned in the introduction, hazardous materials must be indicated by the shipper or producer by law. While the system of classifying physical hazardous materials may seem overwhelming, remember that these laws are here for everyone’s protection and should be taken seriously. There are two main ways you're required to communicate your hazardous material classification.

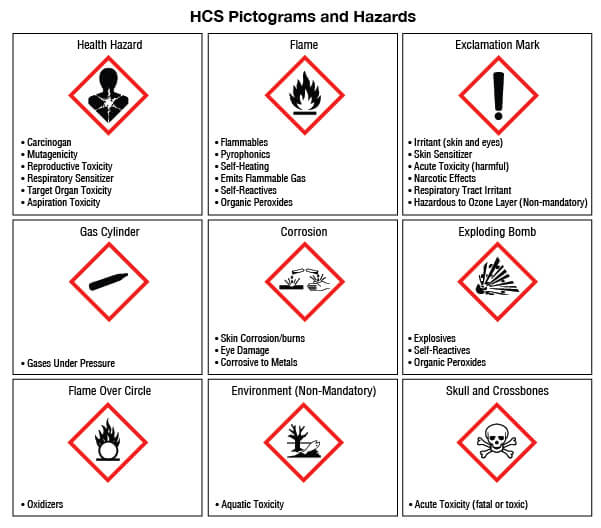

1. Labels and placards

All hazardous materials must be placed in packaging labeled with appropriate symbols and pictograms according to regulations. Appropriate corresponding placards must be placed on cylinders, trucks and transport vehicles. In keeping with our theme of consistency, each pictogram doesn't correspond to a particular class. Rather, multiple classes can fall into the same pictogram.

The pictograms we use in the U.S. were established by the GHS and may be familiar to many chemical workers. For example, toxic substances are marked with a skull and crossbones symbol. But, again, inconsistencies prevail across borders. GHS pictograms have a standard black symbol, white background and red frame. OSHA says materials that aren't to be exported don't require a red frame and can stick with a black frame.

Image Source: OSHA

It's important to note that there are exceptions to laws about labels and placards on hazardous materials in the U.S., specifically for consumer commodities (also referred to as “Other Regulated Materials - Domestic”).

2. Safety data sheets

All hazardous materials must also come with a safety data sheet featuring a hazard statement that clearly communicates the hazard’s class and category. This should be found in section two of the SDS under “Hazards Identification.” The hazard statement should also be accompanied by a corresponding regulatory code and relevant pictograms. The safety data sheet contains all relevant data about the hazardous material, explaining how to safely use, handle, store and transport the product.

Downstream users rely on the information provided in labels and safety data sheets to safely work with the product. They operate on faith and reliance that you, the chemical manufacturer, have performed all necessary tests and made correct determinations.

We hope this article gave you a firmer understanding of how physical hazardous materials are regulated in the U.S. If you’re still concerned about where to start, we suggest you print a copy of the 16 classes and categories, as well as the OSHA pictograms, and study them throughout the day. With this system, memorization of base knowledge is key and lifelong learning is required to stay safe and compliant.

Of course, you always have the option of outsourcing these technicalities! Royal Chemical’s team of chemical manufacturing experts can assist in properly classifying your product, creating safety data sheets and labeling your packaging and transportation.

Talk to a Royal Chemical expert today and get your questions answered!

Talk to an Expert

Streamline Your Chemical Manufacturing Process

Royal Chemical’s expertise in blending, packaging and shipping can save you time, reduce costs and deliver consistent results.