How to Expand Nationally with Help From a Contract Manufacturer

Is it difficult for your business to compete in certain regions, or even nationwide, due to rising freight costs and transit times? Are some of your best accounts vulnerable because a national competitor has entered your market or “safe” geographic area?

While there are many factors to consider when you want to compete with larger companies, especially where they’re established (and you’re not), expanding strategically doesn’t have to be rocket science. One of the easiest ways to expand your product sales into a larger region, or even across the nation, is by working with a contract manufacturer.

Working with a nimble toll blender offers some several advantages to companies looking to expand their coverage area and compete on the national level.

How contract manufacturers help with expansion

If you’re worried about the cost and logistics of getting your product from Point A to Point B, fear not! Contract manufacturers can provide you with the experience and expertise you need to get your products from Point A to Point B, but the benefits don’t stop there.

When you examine the idea from all sides, there are several reasons why partnering with a contract manufacturer makes good business sense for you and your bottom line.

1. Speed up delivery and reduce freight expense. Contract manufacturers manage shipping and freight costs across the country with logistics services that support fast, low-cost delivery.

2. Minimize difficulties with carrier shortages and delays. A toll blender with multiple, certified facilities can help by producing your order closer to its ultimate destination – reducing or eliminating long hauls.

3. Control expenses while ensuring capacity. When your manufacturing is handled by a blender, all of your costs are variable. You can turn them on when you need them, and off when you don't. That flexibility ensures scalable capacity you need to support your growth.

4. Reduce overhead and other costs. For a variety of reasons, contract manufacturing costs can be lower than handling production internally, and many of those operational efficiencies appear on the bottom line. Contract manufacturers can offer lower material costs because they pool the volumes from many customers. Other overhead savings include professional services that accompany national labor, warehousing and management needs

5. Streamline your operations. Reduce your operating expenses (and headaches) by taking advantage of regional warehousing and inventory management services offered by an experienced contract manufacturer.

6. Realize production efficiencies and improve customer service by focusing on your core business. Contract manufacturers specialize on a narrow range of processes, and offer a single point of contact to engage your production.

Bonus: Contract manufacturers in emergency situations (contingency planning)

In addition to the benefits listed above, contract manufacturers also help their clients navigate less than ideal circumstances and emergencies that may arise with a wider distribution area. For example, contract manufacturers can manage regional and seasonal demands as well as maintain product availability when weather (or other) emergencies present unforeseen production challenges in certain locations.

Because the primary ingredient in most Household, Industrial, Institutional (HII) products is water, freezing is a perennial concern. Whether your plant’s production is threatened by a 2-week polar vortex or you don’t want to risk shipping products across the Midwest during a deep-freeze, a good contract manufacturer will have facilities up and running throughout the country, avoiding supply chain disruption.

With a contract manufacturer, emergency planning and logistics services support your company year-round. That way you can assure customers nationwide of product availability, regardless of seasonality concerns or other emergency issues.

Starting your search for a contract manufacturer

With a contract manufacturer, achieving national coverage is easier and more affordable than many manufacturers realize, but your success depends on your partners. Before moving any production line to a contract manufacturer, be clear about your needs and growth goals.

Understanding your manufacturing partner’s capabilities and track record is vital to your sales expansion. Get the information you need about ISO certification, production capacities, chemical packaging options, logistics, and delivery schedules so you’ll be sure you can meet your customers’ expectations. Ask the right questions and take note of any red flags. If there were ever a time to be picky, it’s during the search for the right contract manufacturing partner!

Royal Chemical: your partner in expansion

Royal Chemical is a contract manufacturer with both the experience and expertise needed to get your product to new consumers nationwide. With five facilities strategically placed throughout the country, Royal is the perfect partner in your expansion.

These examples show how some companies working with Royal have already been able to compete more effectively in specific geographic areas, and even nationally:

- After conducting national trials of an oilfield recovery technology, a client was able to respond efficiently to all major oil customers by using our multiple production facilities.

- A major food plant processing cleaner manufacturer with plants in the Midwest worked with us to reduce shipping costs and become more competitive in the Southeast and South-Central US.

- Similarly, a major water treatment provider with plants in the Midwest and Southeast saved money by managing freight costs, which allowed the company to provide better value to its customers in the Northeast.

- A growing carwash company that started in the Midwest added distributors across the nation. Making good use of strategically-located toll blending facilities was key to successfully managing the growing business.

Ready to expand? Get started by taking a look at Royal’s nationwide coverage map here in this location and here is the list of industries we serve.

Talk to an Expert

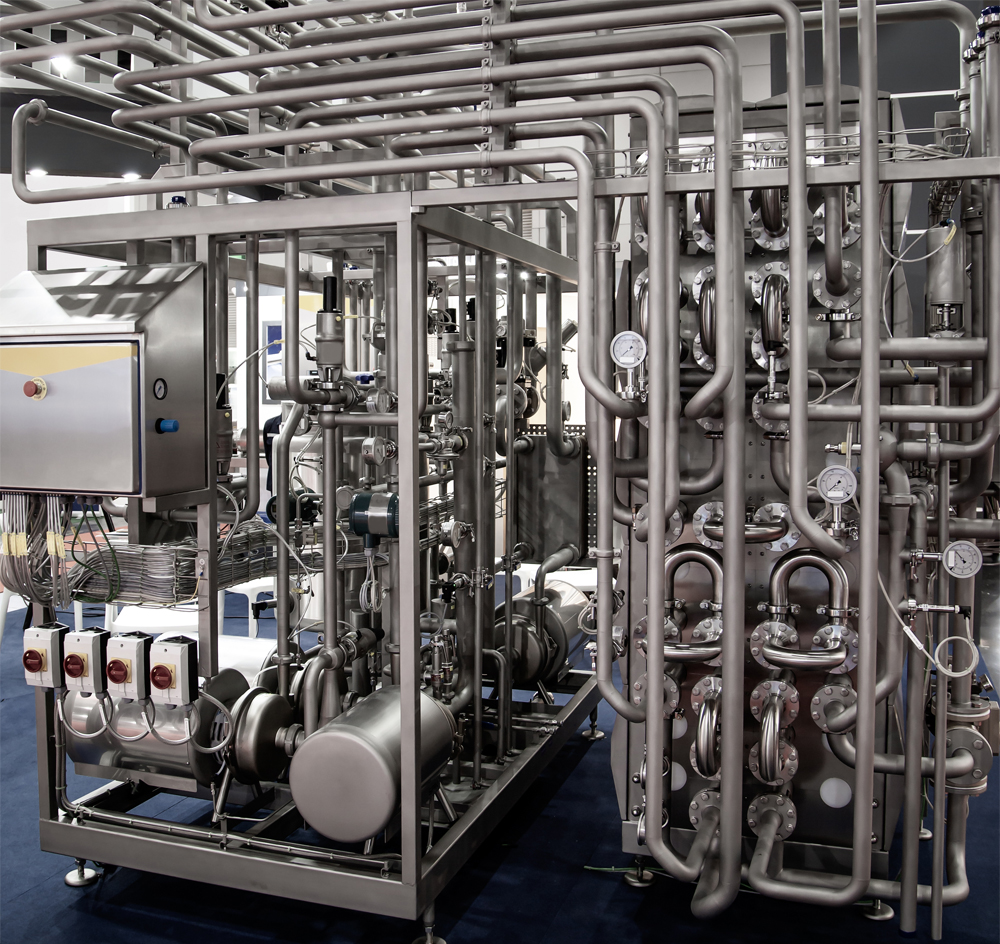

Streamline Your Chemical Manufacturing Process

Royal Chemical’s expertise in blending, packaging and shipping can save you time, reduce costs and deliver consistent results.